More and more, construction companies with strong safety programmes are focusing on reducing the number of injuries on their sites to zero. That includes serious injuries like ladder falls and minor injuries like incidental scrapes and insect bites.

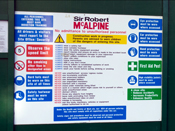

WARNING SIGNS Construction firms say they want you protected from head to toe. This sign on a London construction site notes: “Safety signs and procedures must be observed and personal protection and safety equipment must be used at all times.” But more time spent reducing the risks that make sites so hazardous – by planning out dangerous jobs and processes or reducing the use of toxic substances – is a safer, healthier approach.

This is a commendable goal. No worker should be injured on the job and we applaud companies who take such a serious view on safety. But too often the first solution proposed to achieve this goal of zero injuries is to put all workers in personal protective equipment (PPE).

For example, 100 per cent fall protection programmes often require all workers performing tasks at 6 feet or higher to wear fall protection harnesses. Likewise, many worksites have 100 per cent eye protection policies or 100 per cent hard hat rules. In the UK, hard hats on site are almost always required by law. But while we want all construction workers to be protected, there is a better way to reduce injuries than enveloping them in PPE.

Personal protective equipment is at the bottom of the hierarchy of controls for a reason. It is the least reliable form of protection. It can be uncomfortable, may not offer complete protection and workers don’t like wearing it. It also shifts the burden of protection from the employer, who by law must provide a safe workplace, to the worker.

The hierarchy of controls says first you should attempt to eliminate the risk. Where that is not possible you can reduce it by changing the substances or processes used. And only when all else fails, do you resort to engineering or administrative controls or personal protective equipment. Shouldn’t it be our goal to protect workers in such a way that no one needs to wear PPE to be safe? It may sound far-fetched, but zero PPE is not an impossible dream.

Eliminating hazards

STOP IT Removing the hazard is better than putting on the safety gear.

The best protection from hazards is to eliminate the hazard itself. If that isn’t possible, substitution, process change or engineering controls should be used to reduce or eliminate the hazard. We have been requiring and using PPE for so long that it’s hard to conceive of a workplace or construction site where it would not be necessary. But removing hazards through smart design decisions and engineering controls happens all the time.

Earth Leakage Circuit Breakers (ELCBs) have saved thousands of lives by engineering out the electrical hazard. Guards on saws - or engineering controls like the SawStop, which works like a circuit breaker to stop the saw - have saved thousands of fingers and hands. There are other potential solutions if we are willing to pursue them.

Hearing protection

For many employers, hearing protection involves handing out ear plugs and training workers on their use. But ear plugs must be individually fitted and inserted properly. And most of the commonly available ear defenders can cause issues by blocking out communications from others or making it difficult to hear warning signals or approaching vehicles.

What if we instead made hearing protection unnecessary by designing tools and equipment that operate at safe noise levels, below the action threshold? The US government workplace safety research agency NIOSH has been encouraging contractors to ‘buy quiet’ for years and created a power tools database that includes information on sound and vibration levels for common types of tools.

Fall protection

Safety professionals distinguish between fall prevention and fall protection. Fall protection involves providing harnesses and lanyards so workers can tie off, which prevents them from contacting the ground if they do fall.

SIMPLY WRONG Colin Shields was 34 when he was paralysed from the neck down. The Health and Safety Executive (HSE) found simple safety measures could have prevented his three metre fall from the top of a gritter. The father of two young girls, one born four weeks after the incident, now requires assistance with his day to day care. [more]

Like other types of PPE, fall protection is effective, but can be complicated. For example, where harnesses are used they must be used correctly, have a lanyard - a line for connecting a harness to an anchorage point - that can hold the weight of the fall, be tied off to a suitable anchor, place the anchor properly and be tied off at all times. If workers do fall, they must be rescued in a timely manner before the harness cuts off their circulation. In addition, some feel that fall protection restricts mobility and can cause a tripping hazard. There is also research showing dirt, wear and tear, UV light and other factors can lead to dangerous degradation of the webbing strength of lanyards.

Other forms of fall protection, like inflatable bags or nets, can prevent injuries, but without proper planning might not be where you need them when you need them. Alternative work methods like the use of scissor lifts or cherry pickers, can be an efficient and practicable alternative, but can carry risks of their own.

Given all these factors, fall prevention - for example guardrails to keep workers from falling and better work planning or building design to minimise work at height - seems like a good investment and a better bet than PPE alone. NIOSH has undertaken a number of fall prevention research projects that aim to design fall hazards out of construction, including an easy-to-use guardrail for roofing operations and design solutions such as roof parapets.

Respiratory protection

Like other types of PPE, face masks and respirators come with their share of challenges. They filter chemicals, dust and fumes from the air, but are uncomfortable to wear and present problems for workers who are claustrophobic, have problems breathing or have facial hair that interferes with the seal. Taking the mask off even for a minute reduces worker protection significantly [see: A line in the sand]. And if filters aren’t the right type for the exposure or properly maintained or regularly changed, the mask just won’t work.

BAD EXECUTION Local Asbestos Services Ltd and Construction Contracting UK Ltd had a plan. Rather than have workers risk their lives walking on fragile asbestos roof sheets, they’d use a cherry picker or a scissor lift so workers could safely access and remove the boards from underneath. Only the plan wasn’t used. [more]

Many organisations are looking into replacing the chemicals they use with less toxic ones, for example replacing solvent-based paints with water-based ones. New websites like Pharos are helping employers choose less toxic building materials. The Toxic Use Reduction Institute (TURI), which also has a very useful website, has worked for years to find safer substitutes for chemicals.

Beyond substitution, an increasing number of tools feature built-in engineering controls like local exhaust or water spray systems. Using these controls, manufacturers, contractors and unions in the US worked together to reduce silica exposures in asphalt milling operations to less than half the current UK and US exposure limit so workers did not have to wear respirators.

By challenging ourselves to focus on zero PPE as a goal, we could make the industry safer as a whole and make safety easier for millions of construction workers. It may sound unrealistic, but it can happen if we unhook ourselves from our attachment to PPE. There’s no doubt that PPE helps keep workers safe, but it may not be the best solution and certainly shouldn’t be the only solution.

Scott Schneider is director of occupational safety and health at the Laborers’ Health and Safety Fund of North America (LHSFNA).

Good idea, bad execution

Local Asbestos Services Ltd and Construction Contracting UK Ltd had a plan. Rather than have workers risk their lives walking on fragile asbestos roof sheets, they’d use a cherry picker or a scissor lift so workers could safely access and remove the boards from underneath.

Only the plan wasn’t used. A Health and Safety Executive (HSE) investigation found the firms instead allowed workers onto the roof without safety measures in place. On 5 April 2013, Peter Tracey and a colleague climbed onto the roof. They were removing an asbestos sheet when it started to slip away. As Tracey went to grab it, he stepped onto a clear plastic panel, which gave way under his weight.

The 53-year-old fell through the roof of the disused factory, falling more than five metres onto the concrete floor below. He suffered critical injuries, including two collapsed lungs, fractures to his ribs and hip, and a ruptured shoulder tendon. He was in hospital for a month and will be affected by his injuries for the rest of his life.

In August 2014, Construction Contracting UK Ltd was fined £12,000 plus £23,502 prosecution costs after being convicted of a criminal safety offence. Local Asbestos Services Ltd pleaded guilty and was fined £8,000 plus £6,191 costs.

Simply dangerous by design

Colin Shields was 34 when he was paralysed from the neck down. The Health and Safety Executive (HSE) found simple safety measures could have prevented his three metre fall from the top of a gritter. The father of two young girls, one born four weeks after the incident, now requires assistance with his day to day care.

Colin had mounted the gritter at Inex Works Ltd to help his colleagues dislodge compacted grit salt from inside the machine. The Health and Safety Executive (HSE) found the method used was unsafe as the gritter was not designed with a working platform, walkway or hand rails and Mr Shields was not wearing a harness or restraint to prevent him from falling.

In June 2014, Inex Works Ltd was fined £13,500 after pleading guilty to a criminal breach of the Work at Height Regulations 2005. HSE inspector Hazel Dobb said: “This incident could have easily been avoided as there were several other ways this work could have been carried out, such as using alternative means of access or use of a harness. Tragically, that is a lesson for the company learned too late for Mr Shields.”

Safety unmasked

Hard hats, ear defenders, masks, gloves, safety boots, high viz jackets. It is the standard workplace wardrobe for many workers. But US union safety expert Scott Schneider says removing work hazards is a safer alternative to relying on all this personal protective equipment.

| Contents | |

| • | Introduction |

| • | Eliminating hazards |

| • | Hearing protection |

| • | Fall protection |

| • | Respiratory protection |

| Related stories | |

| • | Good idea, bad execution |

| • | Simply dangerous by design |

Hazards webpages

Vote to die • Deady business